pibo Humanoid Companion Robot Product Design

Product

2019. 5. 5.

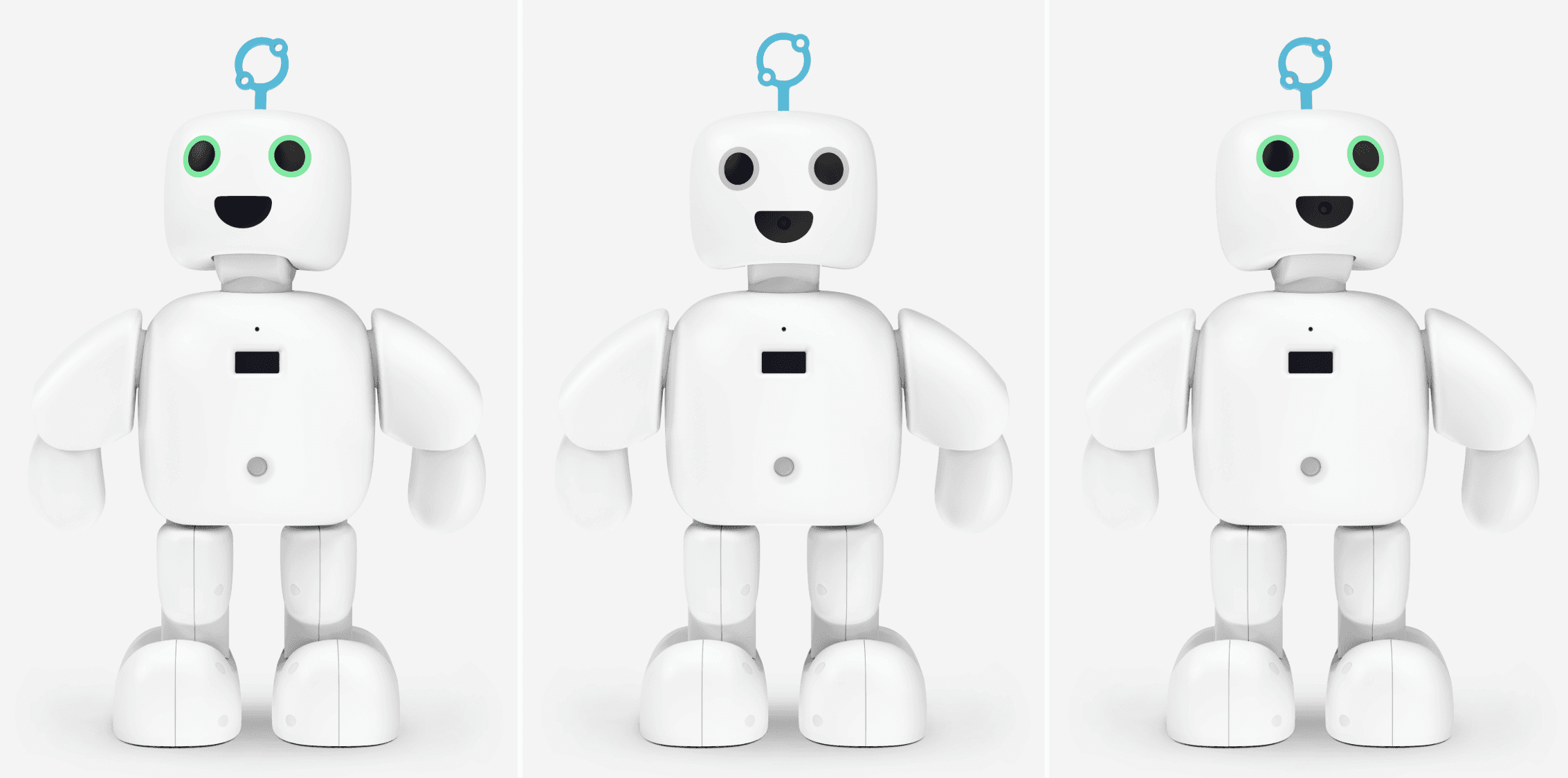

This project transformed an early IoT companion robot prototype—previously limited by exposed internal structures and safety constraints—into a fully market-ready product.

By redefining the exterior and structural design standards to accommodate over 100 components and 10 motors, we established a cohesive design system that extended seamlessly from product design to mold engineering and mass production. The result was a finished, commercially viable humanoid companion robot built for real-world use, not just demonstration.

DESIGN BEGINS WITH RESPONSIBILITY

The moment technology enters the home, design becomes a matter of responsibility—before aesthetics.

Especially for products shared by children and older adults, it’s essential to draw a clear line between what can be exposed and what must be concealed.

This project did not begin with styling a shell around functionality.

It began with defining a form that allows technology to exist safely within everyday life.

WHAT WE WERE GIVEN

The initial companion robot existed only as a basic frame.

Motors, wiring, and PCBs were fully exposed—posing direct safety concerns for users.

At the same time, the robot was built on a humanoid structure, requiring around ten motors to move organically in coordination.

This was not a challenge that could be solved by simply “covering” the exterior.

THE REAL CHALLENGE

The task was clear:

Conceal more than 100 internal components

Preserve natural joint movement

Ensure safety when handled by children

Withstand impact while remaining touch-safe

Be structurally viable for molding and mass production

All of these conditions had to be satisfied—simultaneously.

FORM THAT ALLOWS MOTION

Sphere D did not separate exterior design from structural engineering.

Through dozens of 3D-printed prototypes, joint articulation and shell interference were repeatedly tested and refined.

A single curve radius, a few millimeters of part thickness—

each adjustment was evaluated for its impact on motor movement and long-term durability.

The result was a silhouette that fully protects the internal structure while preserving the robot’s distinctive sense of motion and rhythm.

FRIENDLY BY DESIGN

Technology that children encounter for the first time should never feel intimidating.

The robot’s expression, proportions, and overall presence were designed to feel closer to a companion than a machine.

Soft curves with no sharp edges

A simplified silhouette that hides structural complexity

Balanced proportions and calming color accents

Rather than emphasizing technological presence, the design reduces emotional distance.

FROM PROTOTYPE TO PRODUCTION

Design did not stop at the prototype stage.

Parts were segmented and modeled with mold production in mind, and the structure was further refined to anticipate assembly and durability challenges in mass manufacturing.

As a result, the robot evolved beyond a concept model into a fully market-ready product.

DESIGN THAT FINDS ITS PLACE

Today, this companion robot is used not only in homes, but also in educational environments for children’s coding programs and in care facilities for older adults.

It is an example of design as a vessel—one that allows technology to integrate naturally into diverse everyday settings.

WHY THIS PROJECT MATTERS

This project goes beyond a single product.

It redefines the formal standards required for IoT technology to coexist with people.

A structure that enables motion

An exterior grounded in safety

A design process that carries through to mass production

At Sphere D, we believe design is not the final step of technology—

it is the first gateway through which technology enters society.

Sphere D.

Contact.

support@sphered.kr

+82 70-8098-0775

Location.

Seoul, Korea

Toronto, Canada

Services.

Works.

Copyright © 2025 Sphere D. All rights reserved.

Sphere D | CEO: Hyunyoung Kim | Business Registration No.: 330-33-01418

E-commerce Registration No.: 2025-Seoul Seocho-0075

Address: 11F, 17, Seocho-daero 77-gil, Seocho-gu, Seoul, Republic of Korea